Attaché

Campaign Furniture -

Folding Stool

INFO | Furniture Design

ORGANIZATION | Master of Industrial Design at Pratt Institute

TEAM | Chi-Hao Chiang

YEAR | 2019

CONTRIBUTION | Design Research, Concept Development, Ideation, Mechanism Development, CAD, Prototyping, CNC Milling

A portable folding stool for your modern lifestyle

Concept

There are some problems while using folding furniture.

For folding chairs, it can be folded flatly and the seat height is proper, but it’s too long for people to carry, especially those who are short.

For folding stools, although it’s easy to carry and go, the seat height is too short for people to sit comfortably, especially those who are tall.

Is there a seat that can both have a high enough seat height and a small enough folding volume, just like a briefcase?

Ideation

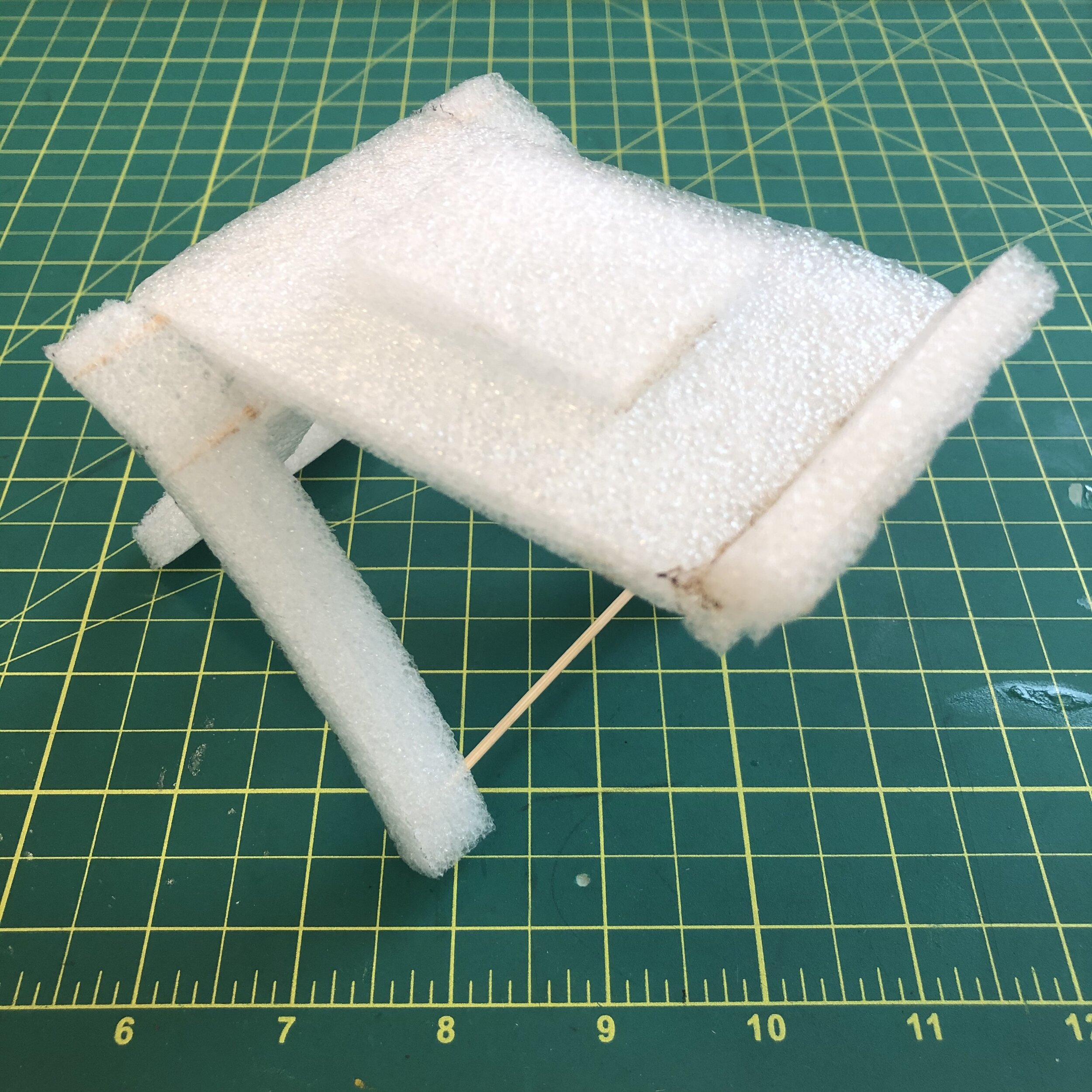

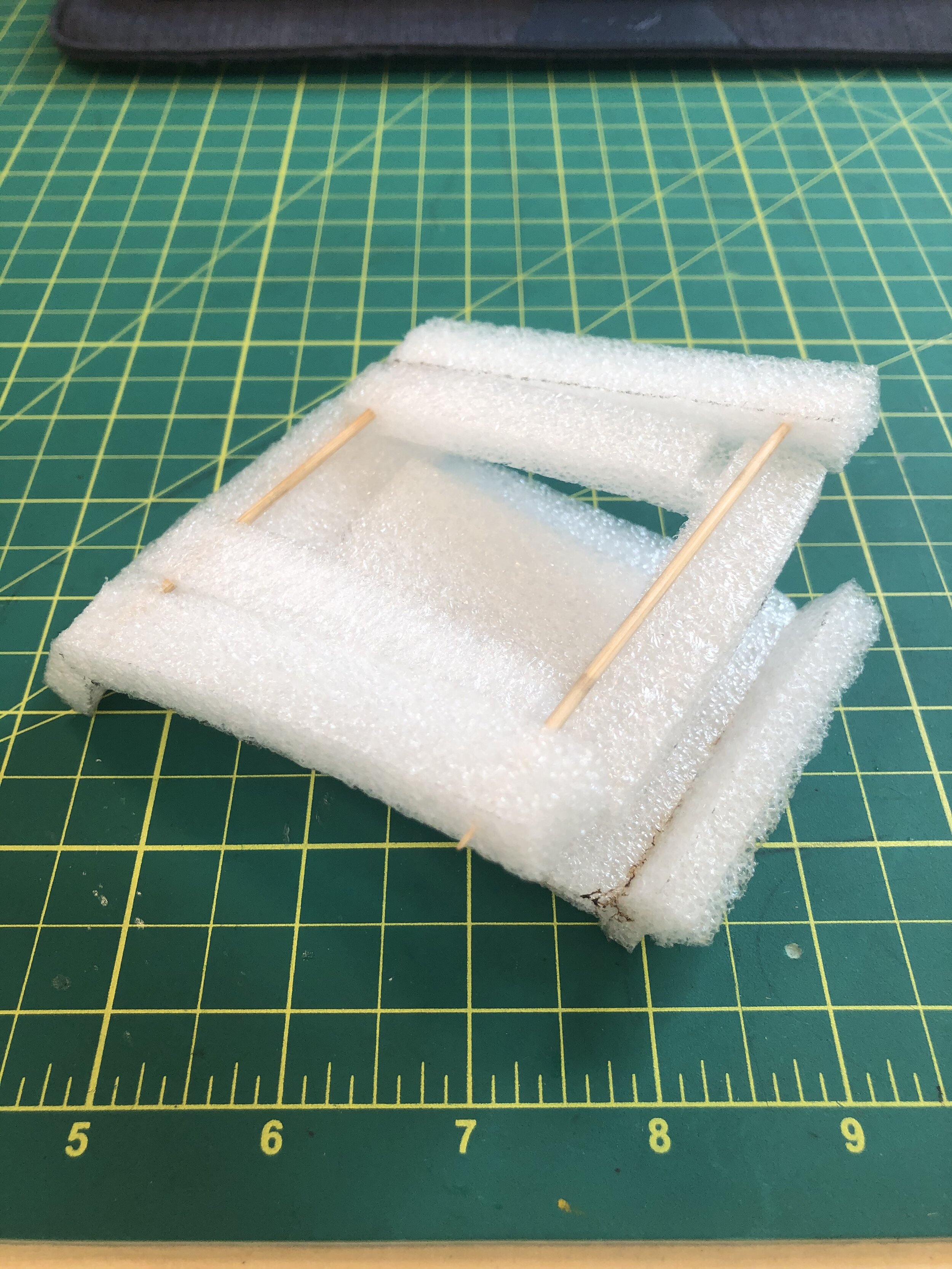

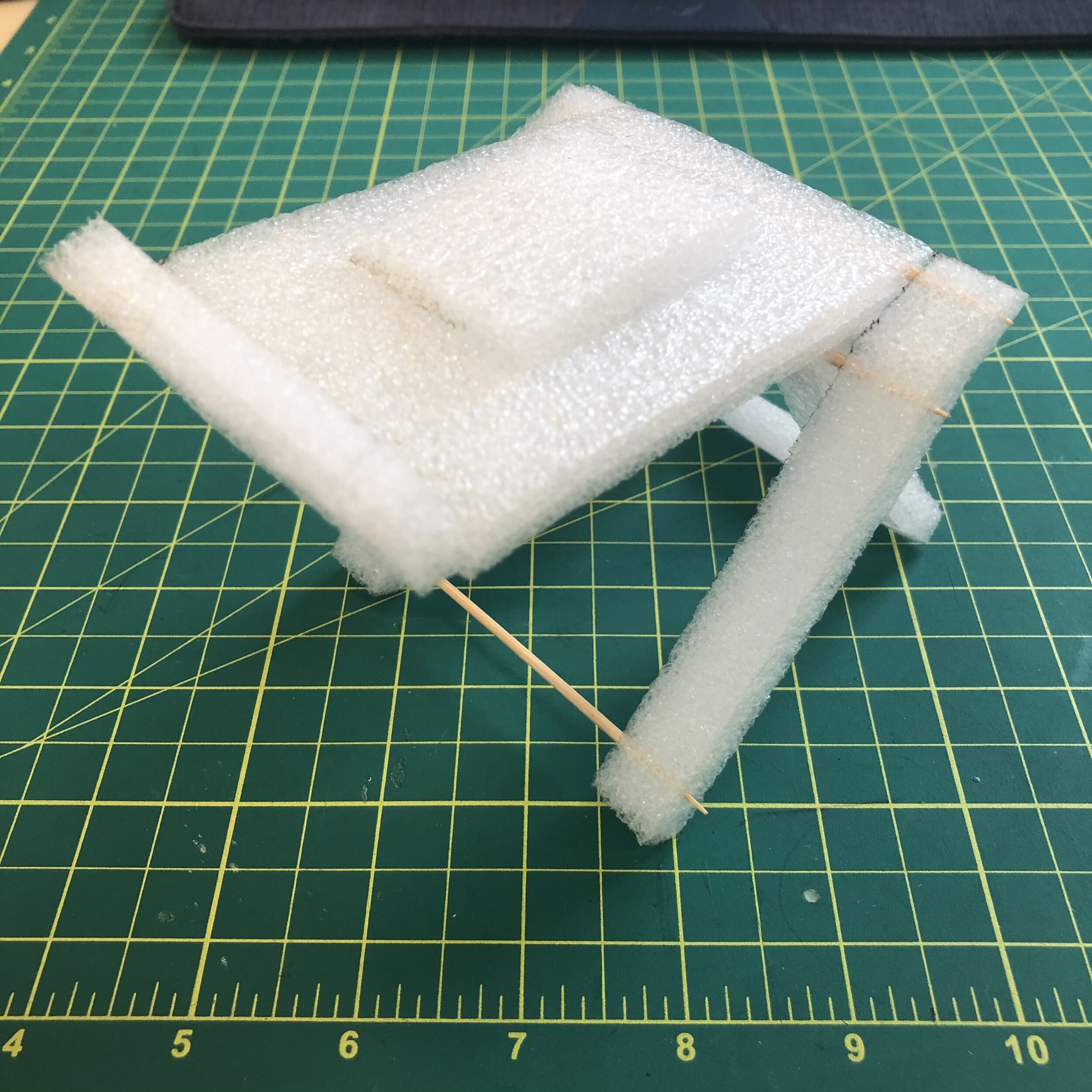

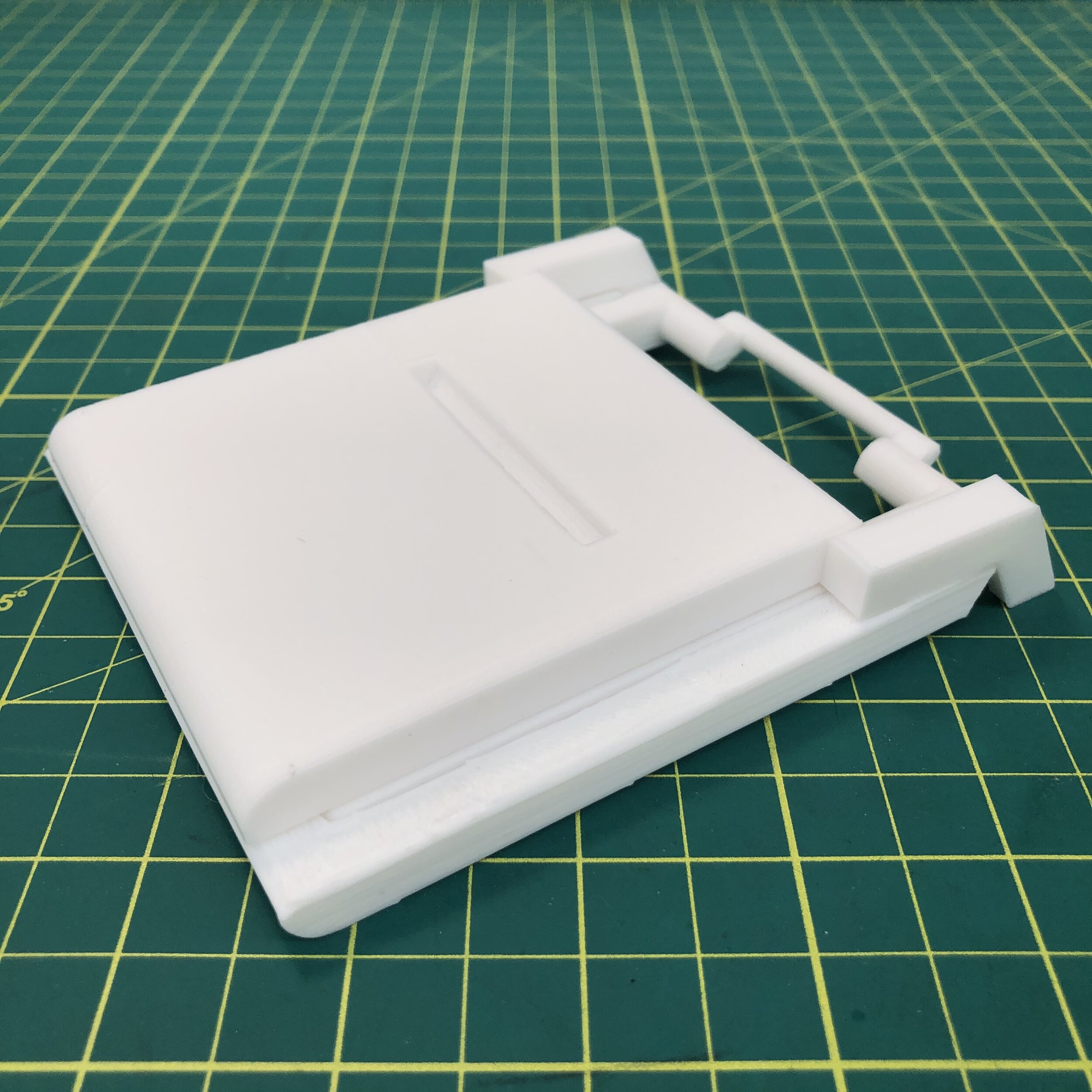

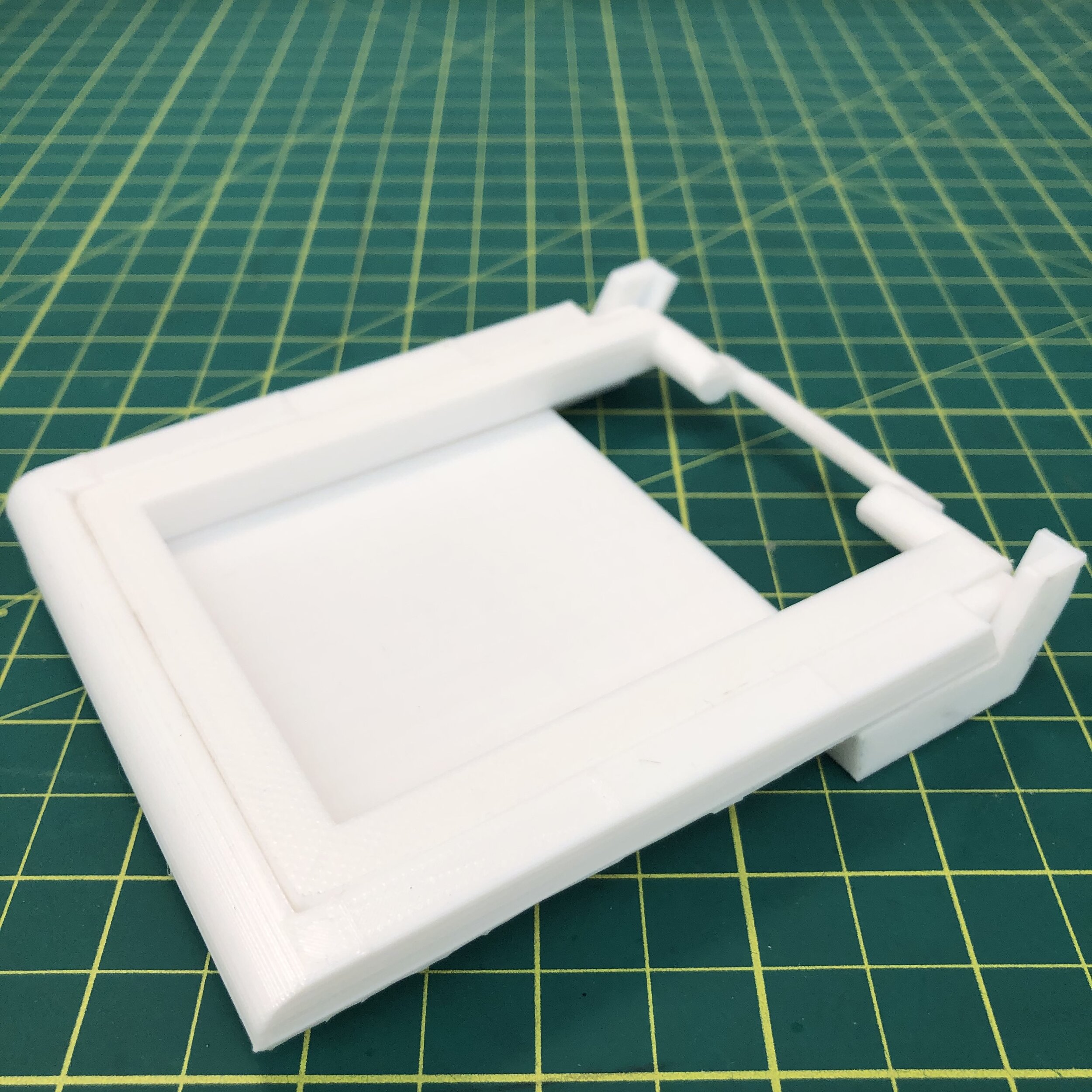

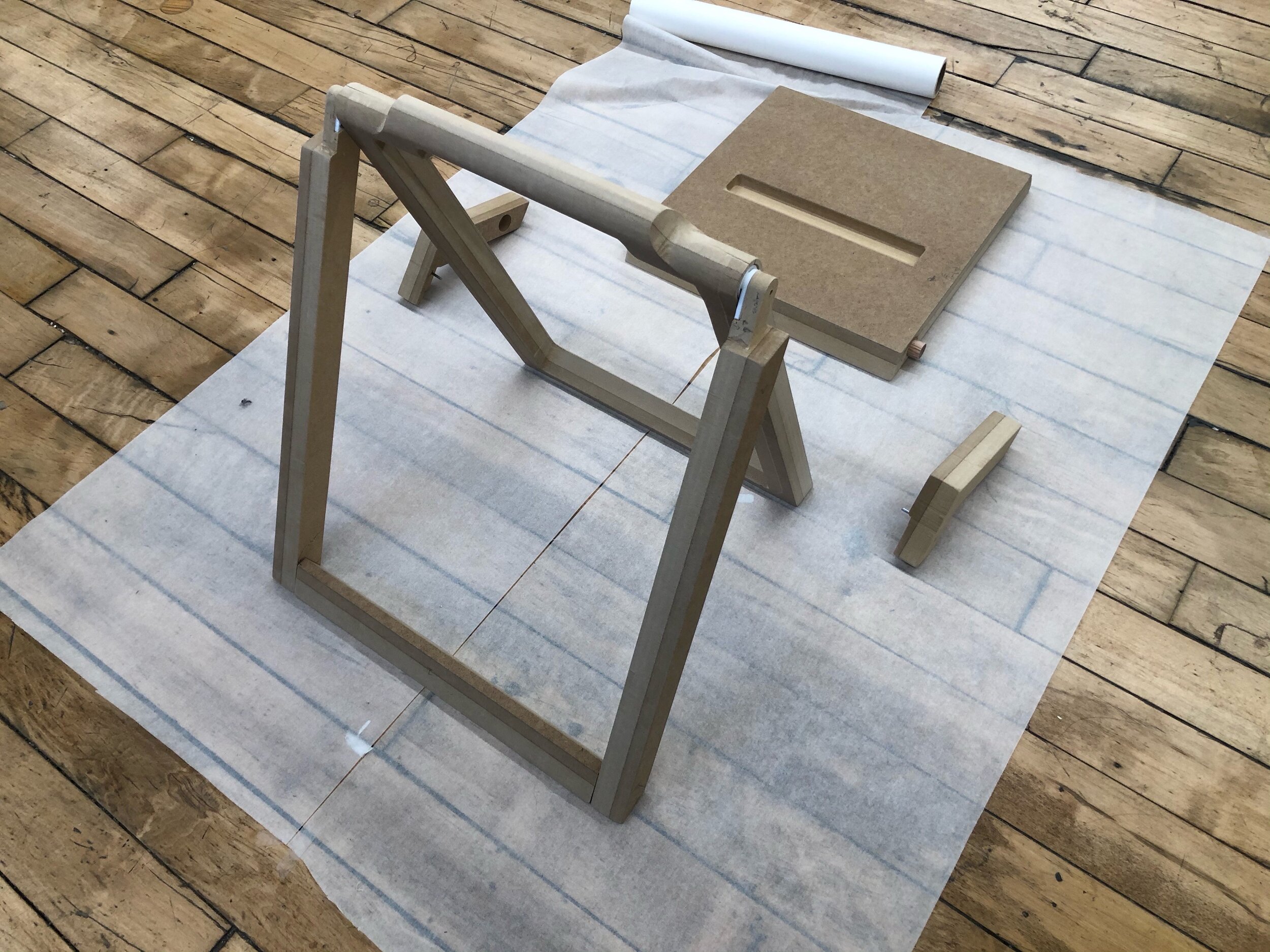

After the first concept came out, small physical mockups were made to test the feasibility.

The result showed that the rear legs couldn’t stand stably with the weight of the seat.

Mockup

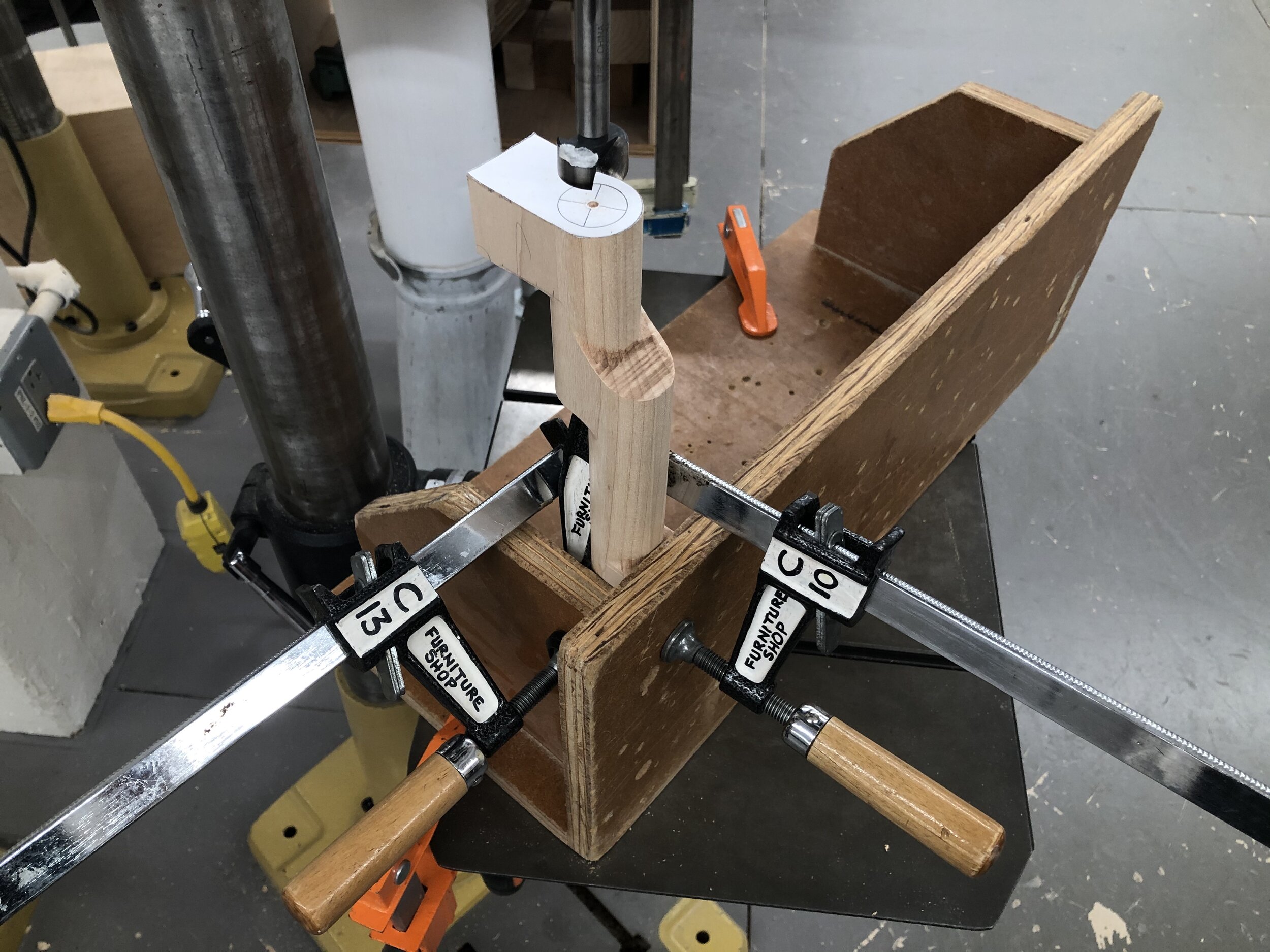

For the second concept, adjust the proportion and thickness of legs, add a notch and latch as a hard stop to increase the stability, also being a handle.

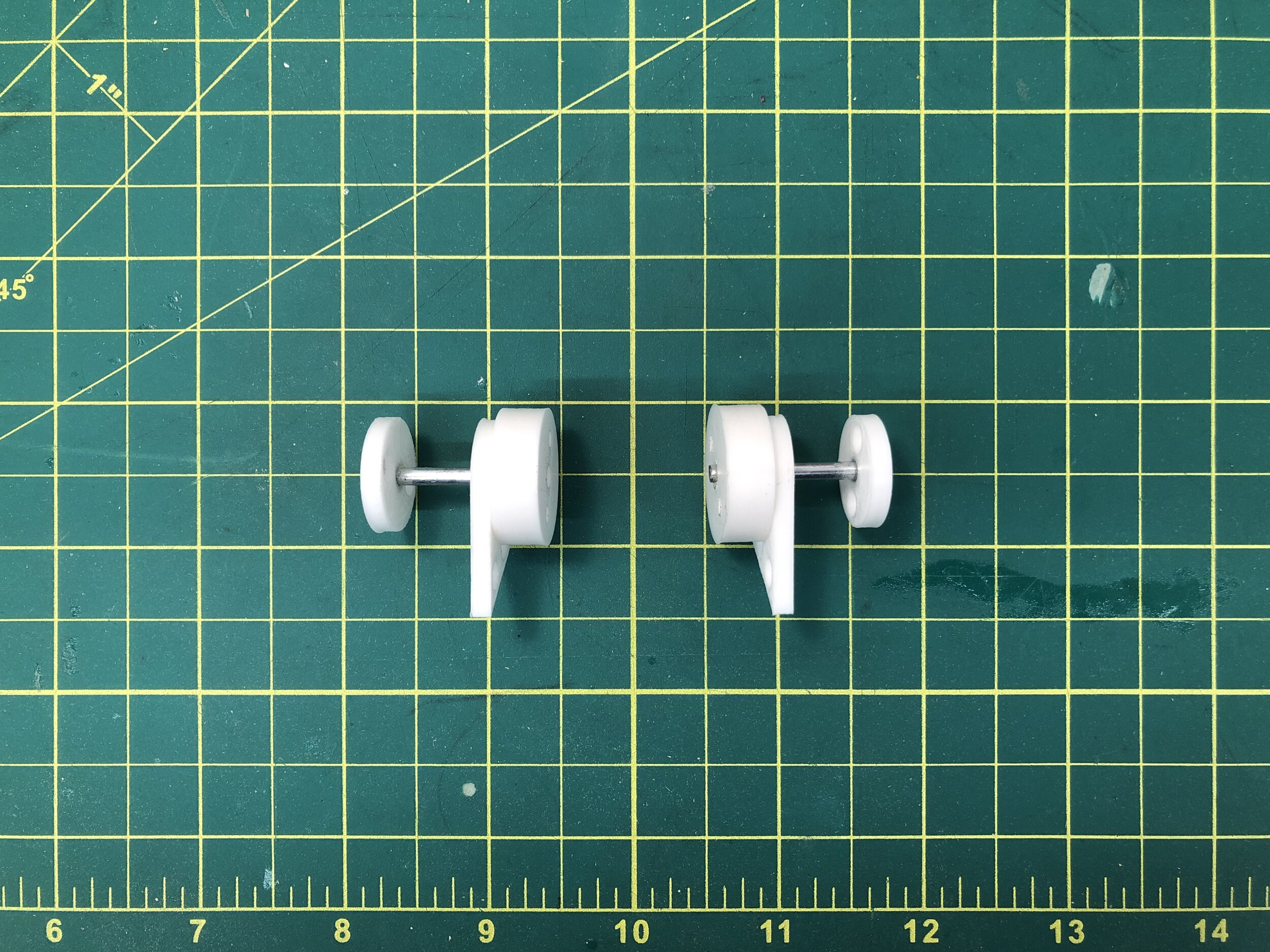

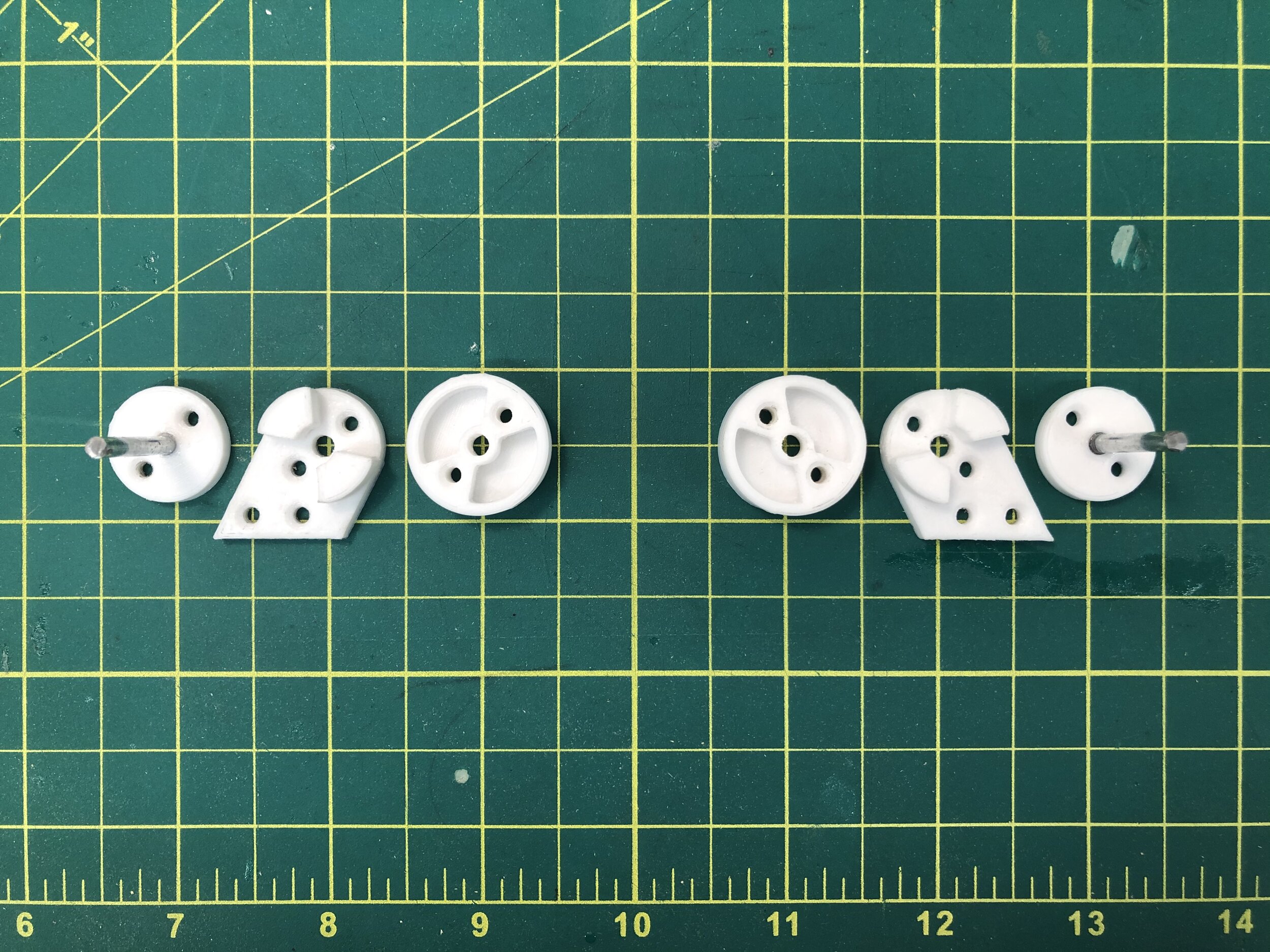

Mechanism

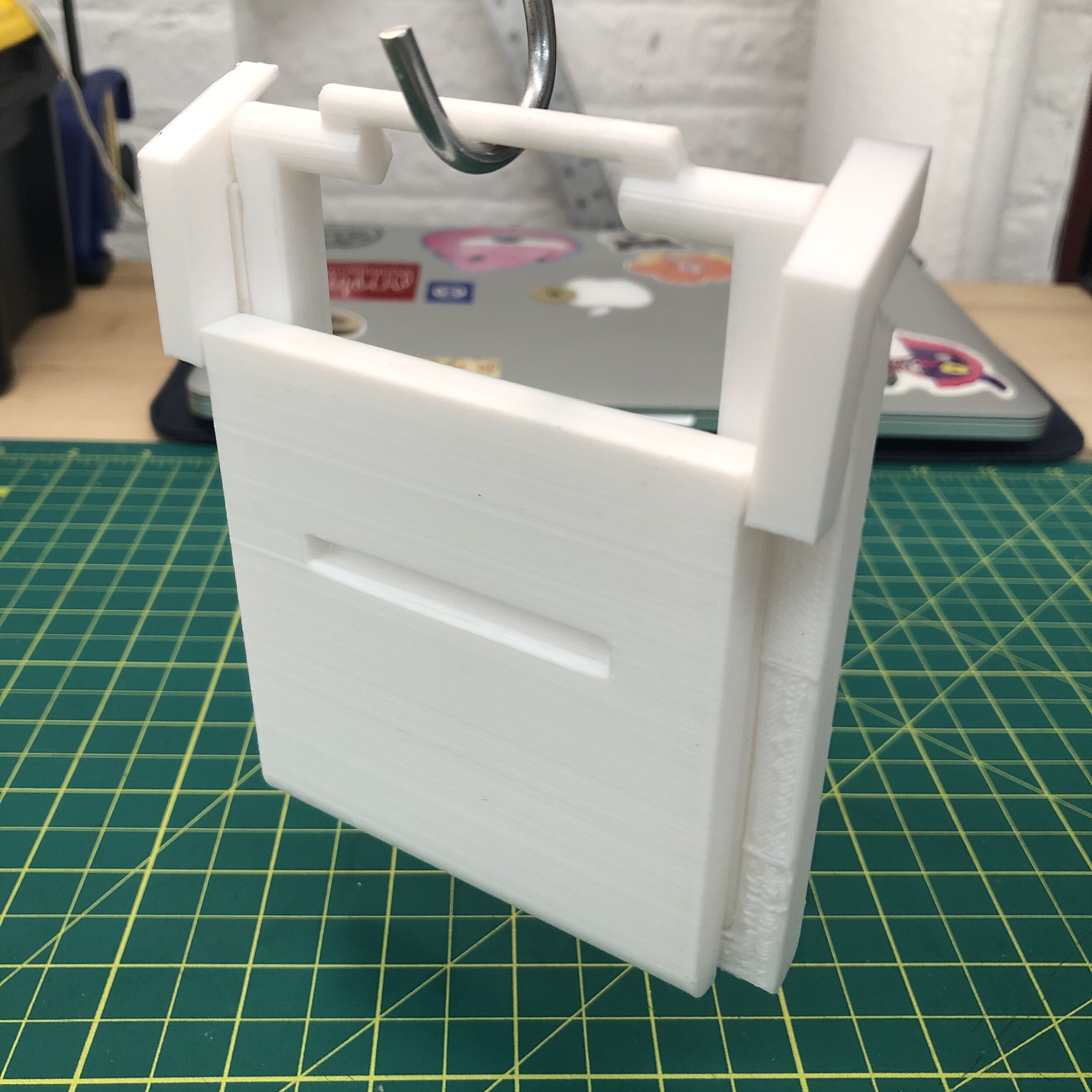

These restricted-angle pivots are designed to increase the bearing strength.

Two teeth on each side would catch into the grooves to make the front and rear legs unfold at a certain angle(45.65 degrees) to stand independently and stably.

Use PLA 3D printing to make the prototype, then use steel 3D printing to build the final precise model.

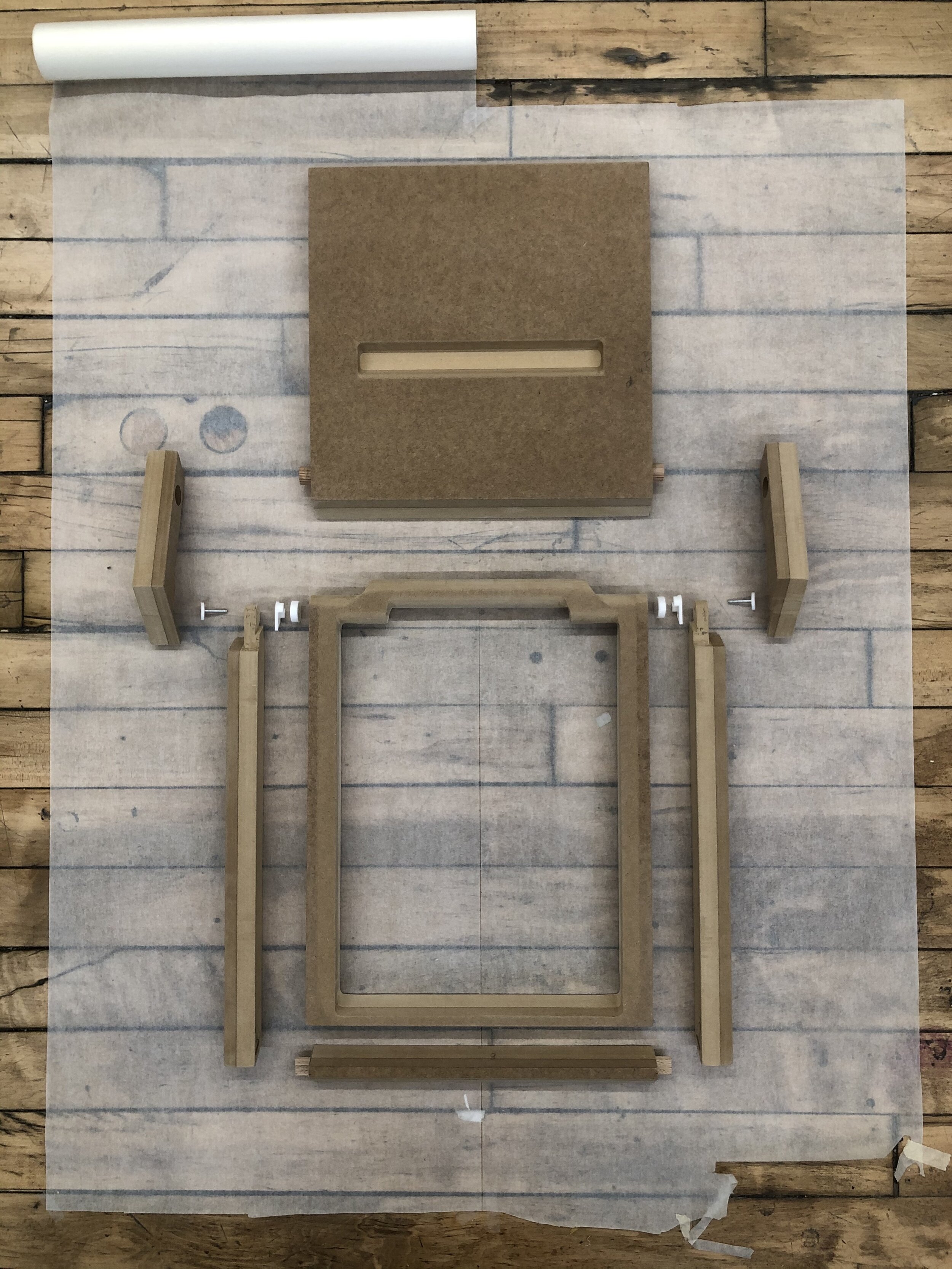

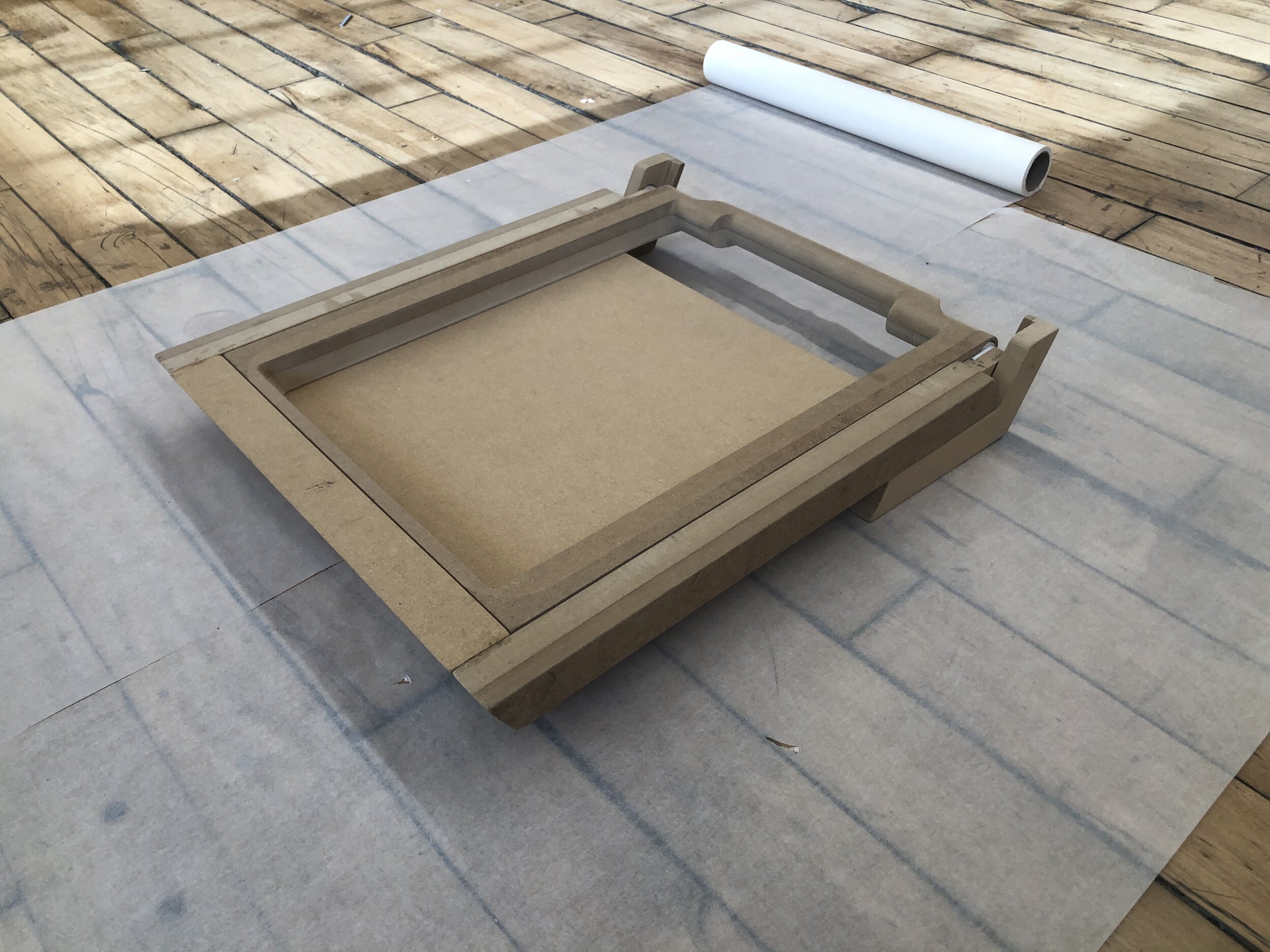

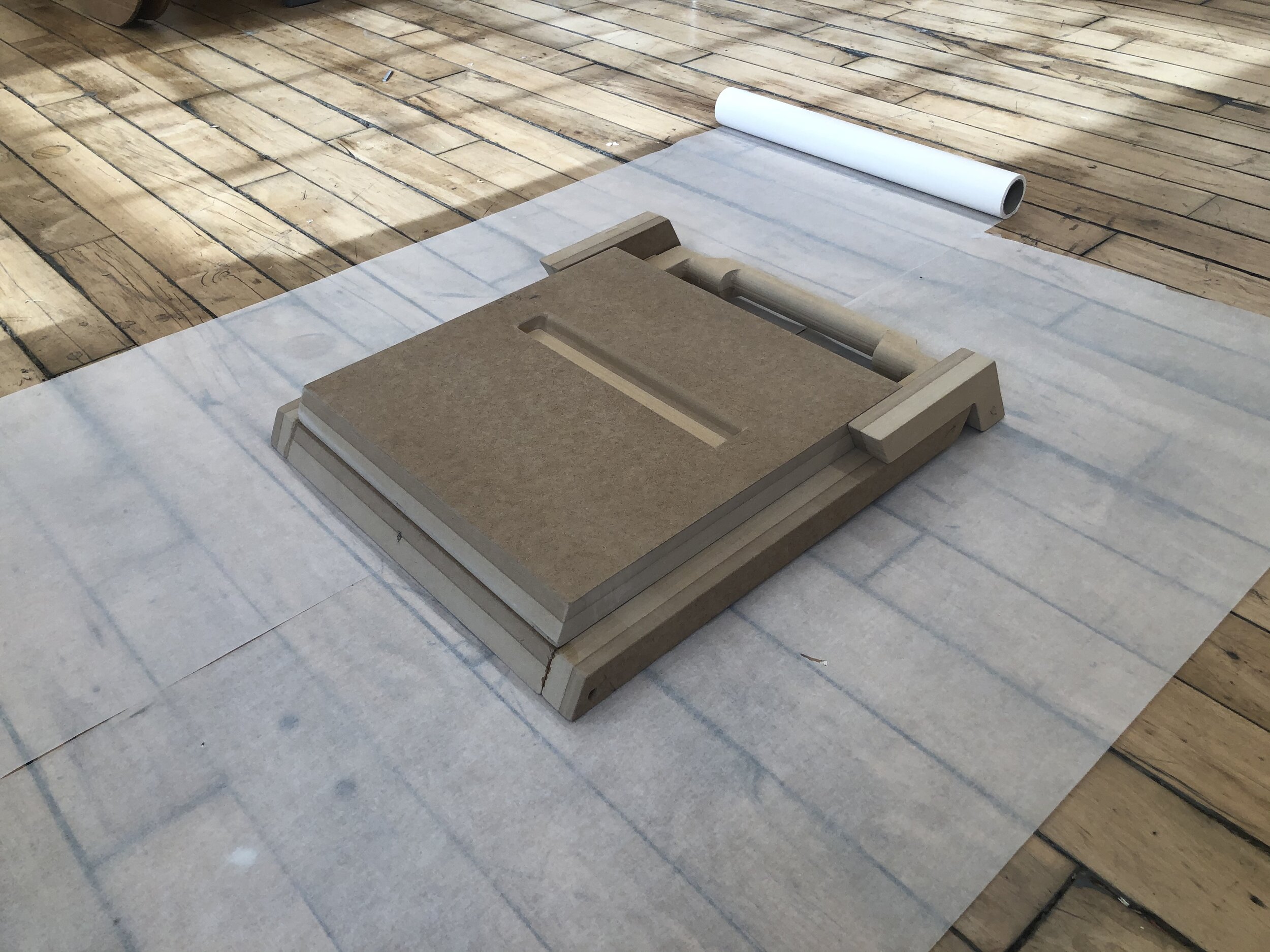

Prototype

Built the 3D model with Fusion 360, defining the angle to make Attaché compactest.

The whole stool followed several angles to have a consistent design language and clean shape both in folding and unfolding types.

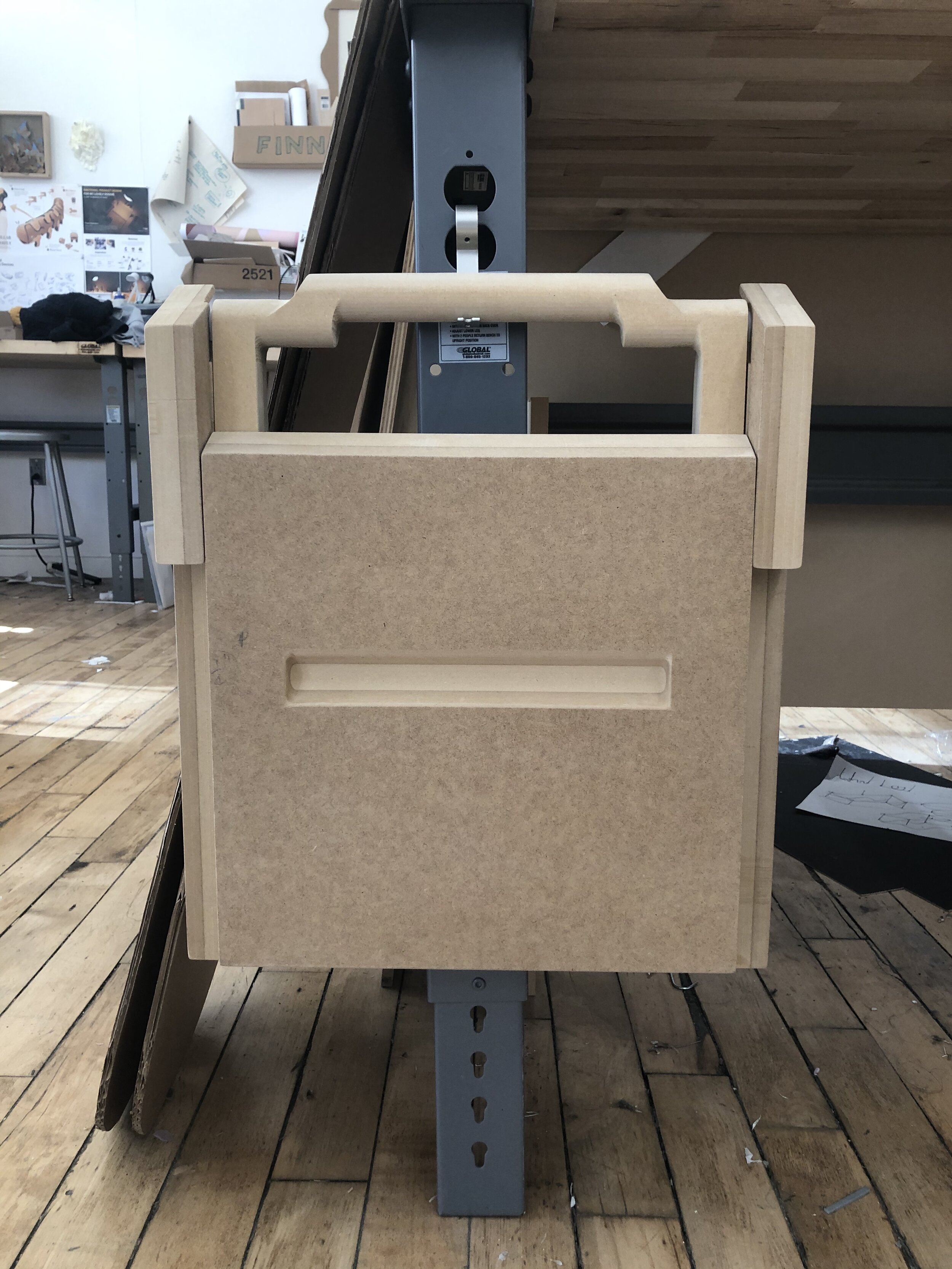

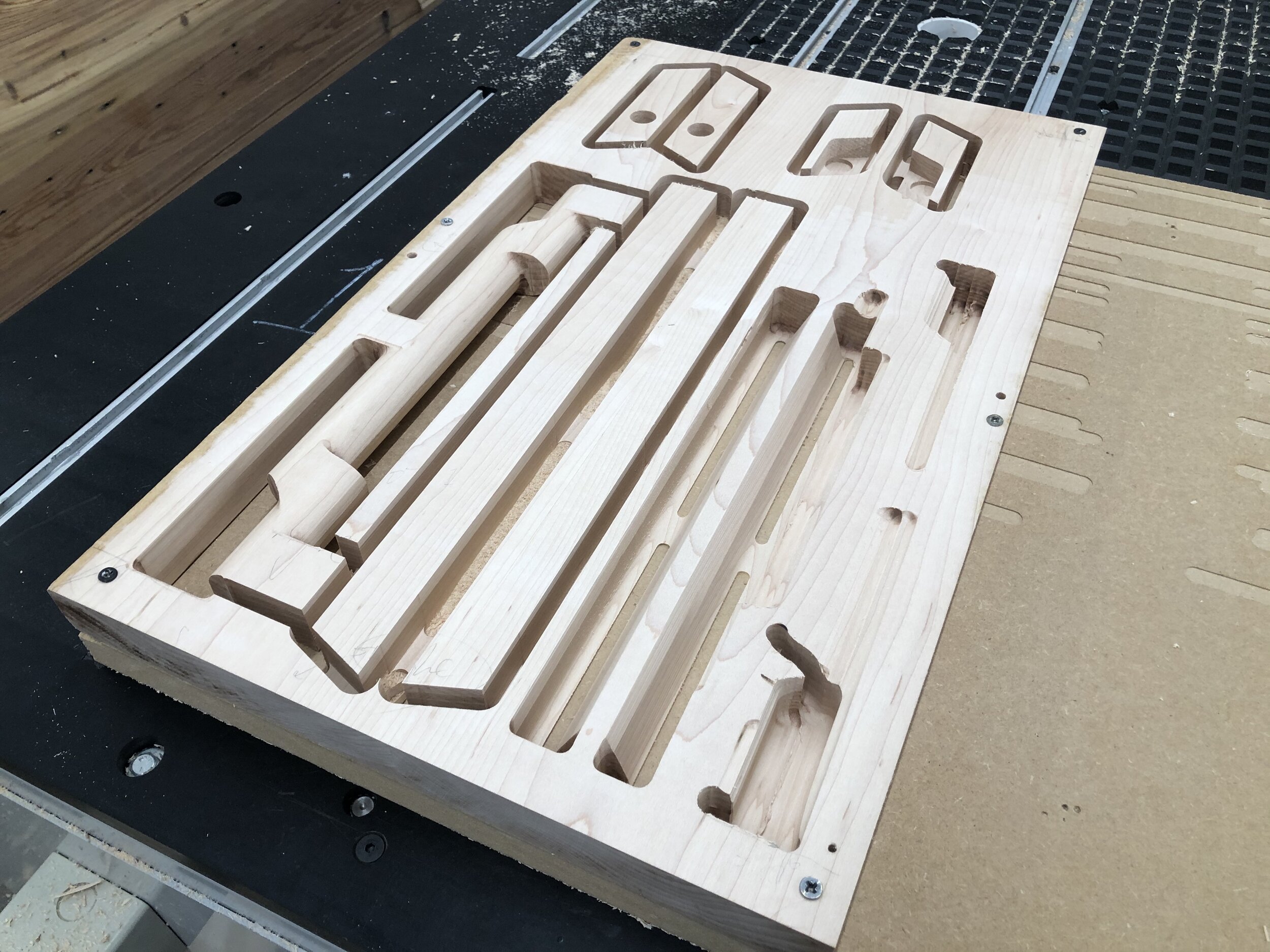

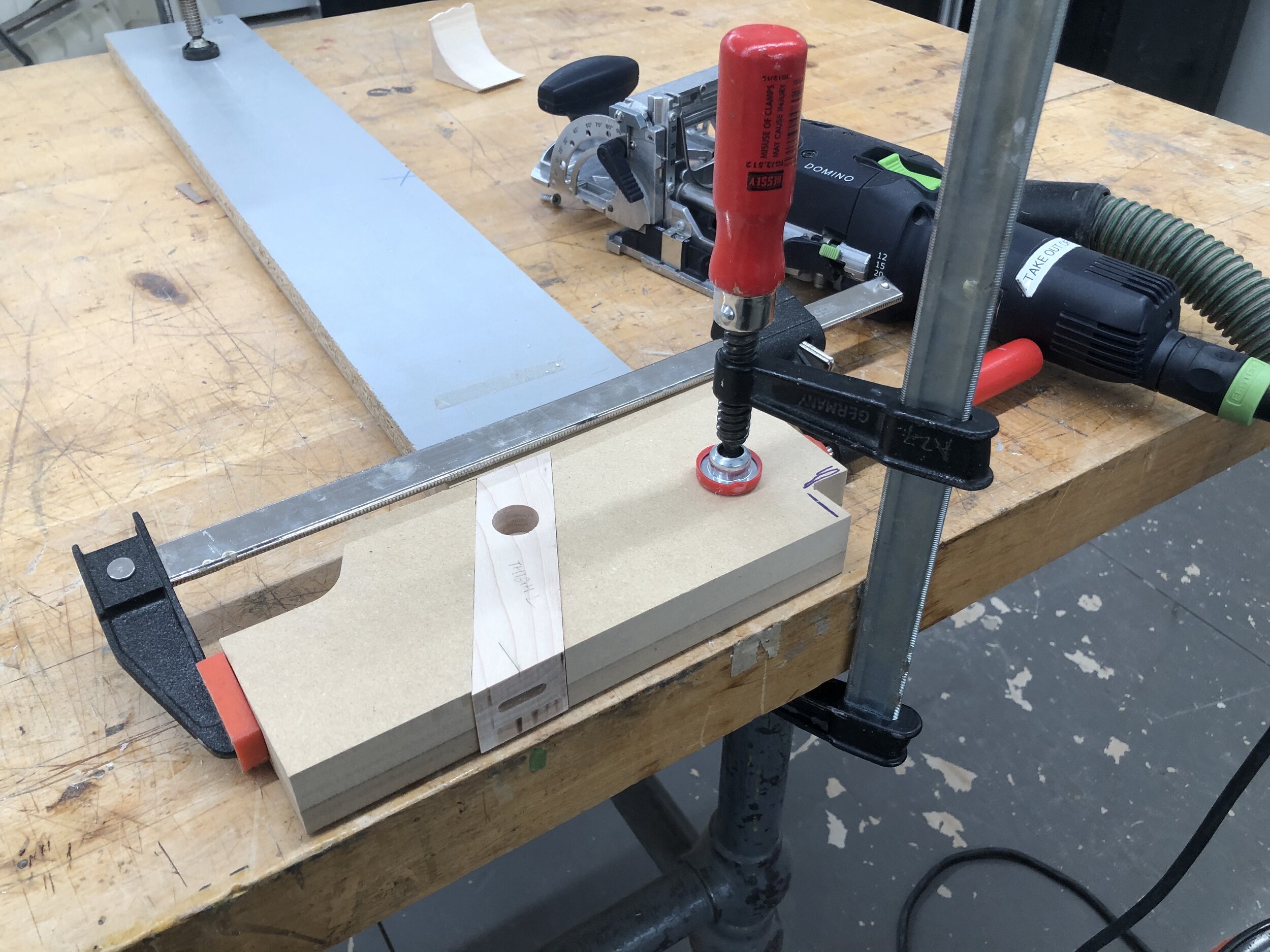

Used CNC machining on MDF to make the full-scale prototype, testing the accuracy of the mechanism and feeling its tangibility.

Process

Final Model

Materials:

Maple/ Steel/ Red Oak

Size:

Unfolding- W16.5” D15” H18”

Folding- W16.5” L19.5” H2.5”

Seat- W14” D15” H18”

Used CNC machining on maple solid wood, screwed on the steel 3D printing pivots, and connected several parts with Domino dowels.